Intellectual

Capital

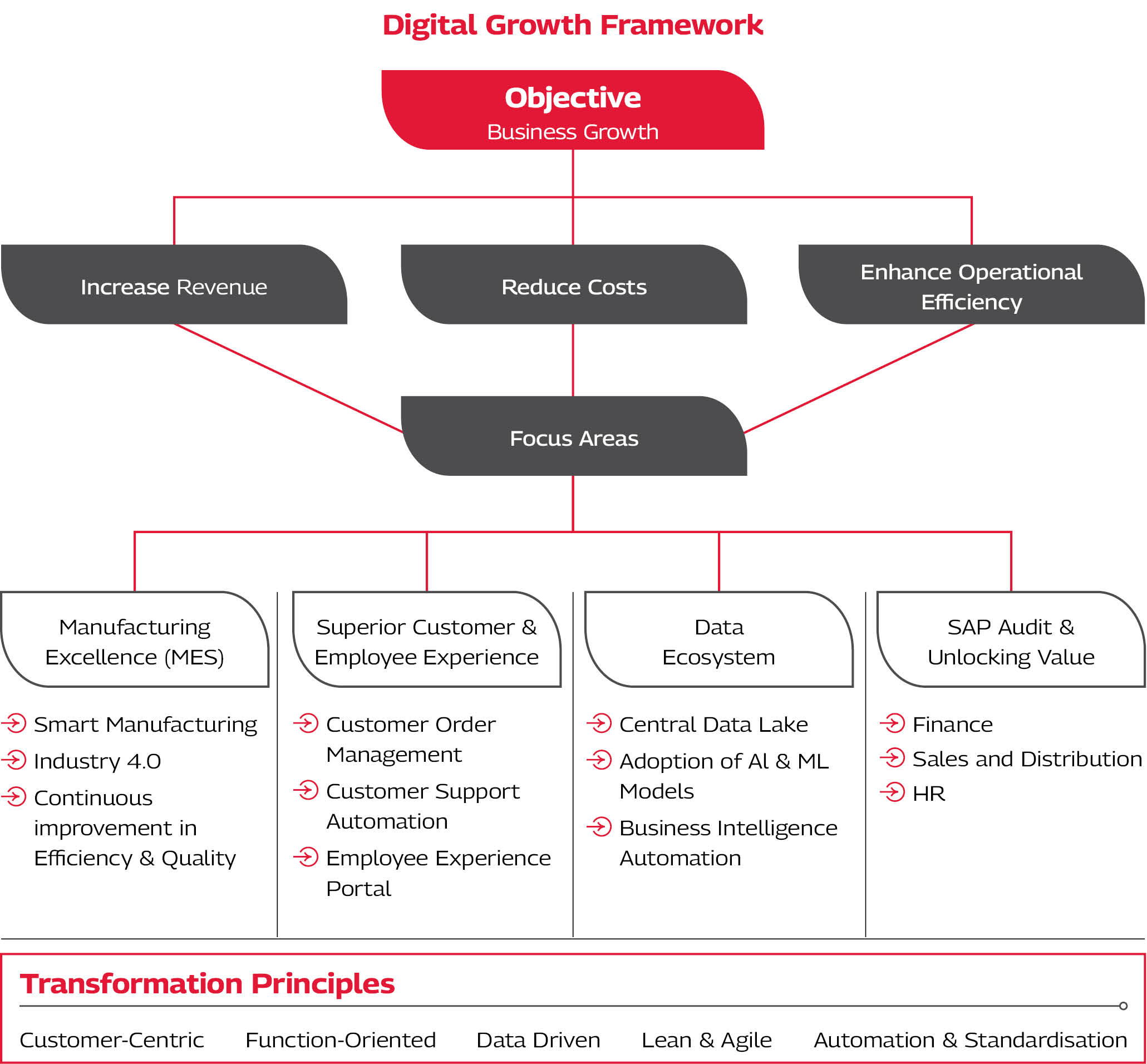

Innovating a Technology-First Enterprise

We are future proofing our business and driving sustainable growth.

At Mahindra Accelo, we are on a mission to become a technology-first enterprise, driving efficiency, agility, and growth through digital transformation. Through cutting-edge solutions in mobility, energy, and sustainability, we are not just adapting to change—we are leading it. From intelligent automation to next-gen employee experiences, our transformation is shaping a smarter, more connected enterprise. With strategic investments, innovation, and a customer-first approach, we are future-proofing our business and driving sustainable growth.

Capitals Impacted

- Financial Capital

- Human Capital

- Manufactured Capital

Stakeholders Impacted

SDGs Impacted

Key Highlights

As part of our transformation journey, we have achieved significant milestones across various strategic initiatives. These include successful implementation of HR SuccessFactors for streamlined workforce management, MES to enhance manufacturing efficiency, and robust data dashboards for actionable insights. Efforts in cleaning and organising data have improved analytics accuracy, while digitising processes and launching customer portals have enhanced operational efficiency and user experience. These advancements reinforce our commitment to building a smarter, more connected, and resilient enterprise.

Pioneering the Future through Digital Excellence

We are spearheading a comprehensive digital transformation to enhance efficiency, agility, and sustainability. Anchored in customer-centricity, data-driven decision-making, and automation, we are leveraging smart manufacturing, AI-driven insights, and business intelligence to optimise operations. By embracing Industry 4.0 and a centralised data ecosystem, we aim to build a more connected, resilient, and innovative enterprise. Our commitment to digital excellence ensures long-term growth, operational efficiency, and an enhanced experience for employees and customers alike.

Vision

Evolve into a ‘Technology-First Enterprise’ that not only supports the growth plans that are put in place for today but can act as a foundation for unlocking hidden values.

Key Focus Areas

Our transformation journey encompasses a range of strategic initiatives designed to optimise operations and unlock new possibilities:

Smart Manufacturing and Industry 4.0

Enhancing automation, connectivity, and real-time decision-making.

Business Intelligence & Automation

Streamlining workflows and improving data-driven decision-making.

Central Data Lake

Creating a unified data infrastructure for seamless access and analytics.

AI & Machine Learning Adoption

Driving predictive insights and operational efficiency.

Vision for the Future

Over the next three years, we are committed to setting new benchmarks in digital innovation. By embracing Industry 4.0 principles, we aim to build a smarter, more connected enterprise that fosters innovation, resilience, and sustained growth on a global scale. Our goal is to enhance operational excellence, empower our workforce, and drive sustainable growth, ensuring that our Company remains at the forefront of the digital revolution.

Our Digital Leadership Initiatives

Manufacturing Excellence

MES Implementation across Plants

Focus

Implementing a Manufacturing Execution System (MES) in partnership with a leading industry provider, seamlessly integrating it into our existing infrastructure to optimise operations.

Creating a unified ecosystem that captures, processes, and analyses real-time data across the entire manufacturing lifecycle.

Development

A comprehensive manufacturing software solution (MES) that provides real-time, paperless production management to drive enterprise-wide compliance, quality, and efficiency was implemented through dedicated modules.

Production Management

Orchestrating production management by real-time tracking of machines, raw material, tools, dies and pallets.

Quality Management

Maintaining quality procedures directly from the control plan for increased process repeatability and predictability.

Inventory Management

Tracking and managing inventory in real time to stay in control with end-to-end traceability.

Impact

- Increasing operational efficiency by eliminating bottlenecks, reducing manual intervention, enabling real-time monitoring, and enhancing overall production speed.

- Implementing rigorous quality checkpoints at every stage of the production cycle to ensure consistent standards.

- Optimising resources and achieving cost efficiency by maximising machine utilisation, minimising downtime, and reducing waste.

- Fostering agile adaptability with best-in-industry predictive analytics for proactive decision-making.

- Leveraging real-time dashboards and comprehensive reports to gain unparalleled insights into production performance.

Future

Implement Auto Production scheduling to:

- Determine which jobs to schedule to which work centres, with resource availability in mind

- Reschedule production plans in case of constraints (change in customer demand schedule, unavailability of inventory, etc.)

Customer Experience

Customer Order Management

Focus

Enhancing customer satisfaction, the implementation of a Customer Order Management System provides a user-friendly platform for seamless order management.

This ensures smoother, more efficient experience for customers throughout the ordering process.

Development

The Customer Order Management System is progressing steadily, with significant steps completed, including journey mapping to define customer touchpoints, designing intuitive screens for ease of use, integrating with SAP for seamless data flow, and conducting User Acceptance Testing (UAT) to ensure functionality and reliability. These efforts are focussed on delivering a streamlined and user-friendly platform for efficient order management.

Impact

- Streamlining Information flow across internal systems

- Facilitating prompt responses to customer requests, reducing turnaround times

- Improving order fulfilment efficiency, ensuring timely delivery

- Ensuring seamless integration with SAP and MRP for accurate production planning and execution

Future

Looking ahead, the system will be further enhanced with advanced analytics and AI driven features to provide personalised customer interactions and faster response times. These improvements aim to elevate customer satisfaction and set new standards for order management efficiency, ensuring a competitive edge and long-term value creation.

Customer Complaint Management

Focus

Introducing a robust complaints management module to ensure efficient issue resolution, this initiative embraces a digitised and interconnected approach to enhance operations. Streamlining internal processes, it fosters a more responsive, customer-centric environment.

Development

The robust complaints management module is under active development, incorporating a digitised and interconnected approach to ensure efficient issue resolution. Key advancements include designing intuitive interfaces, automating workflows to streamline internal processes, and integrating systems for seamless data sharing across departments. These efforts aim to build a platform that fosters responsiveness and enhances customer-centric operations.

Impact

- Addressing customer concerns promptly, fostering a culture of continuous improvement

- Strengthening customer relations through responsive and efficient service

Future

In the future, the module will be refined with predictive analytics and AI-driven insights to proactively address emerging issues and offer personalised resolutions. By continuously improving the system, we aim to create a more agile and customer-focused environment, driving higher satisfaction and operational excellence.

Employee Experience

Employee Experience: Success Factors Implementation

Focus

Revolutionising HR practices with an agile, data-driven, and employee-centric approach, it offers a comprehensive solution for end-to-end human capital management.

Unifying diverse HR functions, it creates a seamless experience for both employees and HR professionals.

Development

Phase-1 implementation focused on employee life cycle commencing with recruitment, onboarding and employee central.

Impact

- Enhancing employee experience

- Data-driven decision-making

- Boosting scalability and future-readiness

- Improving commitment to employee well-being and organisational growth

Future

Future projects include AI enablement and related features in HR modules to accelerate employee experience.

Launch of AcceloKonnect

Single Interface for All Employee Needs

Focus

Streamlining workforce management, it consolidates all employee-related functionalities into a single interface.

Simplifying access to HR services, tools, and resources, it empowers employees to efficiently navigate their professional journey.

Development

At Mahindra Accelo 8 independent portals were being used daily by over 400 employees. To address this, AcceloKonnect was developed, consolidating all employee-related functionalities into a single interface. With 30+ modules, it integrates HR policies, communication channels, repositories, daily ticket handling, organisational announcements, reporting, compliances, and more, streamlining operations and enhancing efficiency.

Impact

- Enhanced employee engagement

- Efficiency and productivity boost

- Personalised experience

- Centralised information hub

- Improved HR service delivery

Future

- Integrating AcceloKonnect with SAP Successfactors

Creating AI agents to help employees have a level of autonomy to make decisions, learn, and adapt.

SAP Audit and Unlocking the Value

Improving RM Planning: Custom Material Resource Planning Report

Focus

Enhancing operational efficiency, a custom tailored Material Requirements Planning (MRP) report was implemented to meet organisational needs.

Overcoming the limitations of Excel-based planning, it enabled proactive decision making with accurate, real-time visibility for future demand planning.

Development

This initiative overcame the limitations of Excel based planning by designing a solution that offers accurate, real-time visibility into material requirements. Key efforts included system integration, report customisation, and testing to ensure reliability and alignment with business processes.

Impact

- Ensured timely closure of open purchase orders for improved process flow

- Advanced raw material planning

- Enhanced accuracy and decision support, boosting operational efficiency

Future

The future of the MRP report lies in integrated planning powered by AI. By leveraging AI-driven insights and predictive analytics, the system will enable smarter, more dynamic planning processes. This will ensure greater accuracy, adaptability, and efficiency in demand forecasting and material management, driving strategic decision-making and operational excellence.

Data Ecosystem

Orchestrating a Data Ecosystem

Focus

Developing a comprehensive Data Ecosystem, aligned with transformative initiatives, to unlock the potential of vast data. Aiming to convert data into actionable insights, it enhances decision-making by integrating data from diverse sources and providing stakeholders with advanced MIS dashboards. Revolutionising decision-making, it offers improved data visibility, facilitates smooth data flow, eliminates silos, and delivers a unified view of organisational performance.

Providing customised MIS dashboards with intuitive visualisations and KPIs, giving business users real-time visibility into key metrics and performance across all functional areas.

Development

The development of a comprehensive Data Ecosystem is progressing with key initiatives, including the creation of a centralised Data Lake to consolidate data from diverse sources. Efforts are focused on data cleaning and standardisation to ensure accuracy and consistency, along with designing custom reports and advanced dashboards. These dashboards provide intuitive visualisations and KPIs, offering stakeholders real-time visibility into metrics across all functional areas, thereby supporting improved decision-making and operational efficiency.

Impact

- Informed and data-driven decision-making

- Operational excellence and continuous improvement

- Strategic alignment and performance monitoring

- Increased visibility

Future

Looking ahead, the Data Ecosystem will be enhanced with advanced analytics, AI, and machine learning capabilities to transform data into actionable insights. This unified platform will revolutionise decision-making by providing greater data visibility, predictive insights, and a holistic view of organisational performance, enabling more informed and strategic actions across the enterprise.

Our Forward Planning for FY 2025-26

For FY 2025-26, the organisation is set to advance its digital transformation journey with a range of strategic initiatives designed to enhance operations and scalability. These include leveraging AI for integrated raw material planning and applying Vision AI for precise lamination sheet measurement. The expansion of the Manufacturing Execution System across more locations will further optimise manufacturing processes, while the development of a centralised data lake will unify data management for better decision-making. Efforts will also focus on completing the implementation of the remaining HR SuccessFactors modules, enhancing the Lead Management System to streamline lead tracking, and introducing a capex portal to improve capital expenditure management. The organisation will further enhance operational efficiency by automating cranes at additional plants, fully unlocking SAP capabilities, and implementing robust solutions such as a Contract Employee Management System to streamline workforce management and a Logistics Management System to optimise supply chain and transportation processes. Separate digital solutions will also be implemented for financial reporting and the Contract Lifecycle Management System.

In the long term, the organisation envisions creating a fully connected, intelligent ecosystem by adopting advanced technologies. This includes the development of digital twins for real-time simulation, transitioning to AI-first manufacturing processes, and integrating AI into existing digital projects to enhance their effectiveness. Advanced analytics will also play a pivotal role in providing predictive insights to drive smarter, data-driven decision-making. These transformative initiatives will position the organisation as a leader in digital innovation, enabling long-term growth and resilience.

Driving Excellence through Product and Process Innovation

At Mahindra Accelo, we believe in innovation as the cornerstone of our journey. Our persistent drive to challenge boundaries and shape the future inspires us to revolutionise the industry. By harnessing cutting-edge technologies, we remain committed to excellence—whether in crafting pioneering products or refining our operations for unparalleled efficiency.

Mobility Evolution: Advancing as a Tier-0.5 Auto Component Leader

We take pride in being a dynamic and innovative force in the automotive steel supply chain, constantly evolving, pushing boundaries, and adapting to the ever-changing market landscape.

From a steel coil supplier to a high-end component leader, our transformation is driven by innovation, advanced machinery, and a strong distribution network.

Our cutting-edge facility processes up to 1,200 MPA steel, serving as a gateway for expansion into multiple product lines and OEMs.

We have developed new cutting-edge progressive stamping technology, including a 1,500-tonne progressive press line at Chakan.

It has helped us secure new OEM customers and achieve Tier-1 supplier status. Additionally, our latest automotive steel plant in Chennai has expanded our customer base beyond M&M, offering an innovative product mix and high-tensile processing capabilities to meet evolving market demands. With advanced machinery designed to handle high-tensile steel, we continue to enhance our competitive edge in the market.

We aim to position ourselves as a Tier-0.5 player in the automotive component industry by making strategic investments in cutting-edge technology.

Investments such as acquiring one of India’s first high-end tandem and transfer presses are key to our strategic growth.

Driven by our pioneering spirit, we established India’s first merchant blanking line in Nashik, marking our entry into the steel blanking/profiling segment. With a focus on technological advancements and recognising the shift towards thinner, stronger, high-strength steel, we launched India’s first servo blanking line at Mahindra Accelo in Chakan Plant, located in the western automotive hub of India. This state-of-the-art facility further strengthens our capabilities.

These press lines are highly versatile, capable of processing aluminium, which aligns with the upcoming EV revolution. As forward-thinking industry leaders, we have pioneered the development of fully automatic robotic laser welding lines. With these advanced welding capabilities, we can deliver critical assemblies to automotive OEMs for both EVs and ICE vehicles.

At Mahindra Accelo, we have made significant investments in product development to meet the growing demand for EV components, including the successful development of EV battery enclosures.

Through collaborations with global leaders in aluminium processing (stamping, forming, welding, deburring, cleaning, and inspection), we have delivered prototypes for EV battery enclosures. Additionally, all our upcoming stamping lines will be equipped to process aluminium, demonstrating our commitment to evolving customer needs and staying ahead of industry trends.

Our New Offer Beyond Steel

We now offer aluminium enclosures to meet the lightweight requirements of the EV industry.

This initiative aims to increase our business share with existing customers and penetrate new automotive OEMs.

These presses are capable of producing skin panels and Class A/B critical components for both electric vehicles (EVs) and internal combustion engine (ICE) 4-wheelers.

Powering Growth: Technology-Driven Expansion and Customer Acquisition in the Energy Sector

Our innovative approach to the electrical steel segment, particularly in Cold Rolled Grain Oriented (CRGO) steel, has significantly enhanced our market presence while driving cost efficiencies. By offering cut-to-size laminations and value-added products such as built-up cores and flux plates, we are able to meet the diverse needs of customers, especially transformer manufacturers. This allows them to focus on their core business while minimising inventory and storage costs.

Our strategic investment in high-speed cutting lines—capable of processing complete transfer logs simultaneously—has enabled us to tap into new markets, particularly in Europe, where demand for our products is growing. With access to world-class machinery for processing electrical steel, a capability shared by only a select few companies in India, we excel in delivering high-quality CRGO steel.

As leaders in the sector with a substantial annual supply capacity, we are poised for continued growth. Our newly inaugurated cutting-edge facility in Indonesia further strengthens our position in Southeast Asia, enabling us to offer an even broader range of products.

Energising New Markets: Expanding Our Reach in Electrical Stampings

Our journey in the electrical stamping business began with supplying stators and rotors for home appliances. Driven by innovation, we leveraged our advanced investments and machinery to expand into the Electric Vehicle (EV) segment, which has now become a significant growth driver for Mahindra Accelo. We are strategically focusing on the EV segments going forward.

Our dedication to quality and customer satisfaction has been affirmed by our selection as a motor core supplier to one of the world’s largest automobile motor manufacturers, serving both domestic and European markets. We now supply motor cores and stampings for electric 2-wheelers, 3-wheelers, and 4-wheelers, solidifying our position in this rapidly expanding sector.

In the 2-Wheeler segment, we are the first company to start a hub motor slinky line, a specific technology in which the stator is produced by a spiral winding method, providing high material yield. In the 3-Wheeler segment, we supply induction motors and PMSM motor stacks for the 3W industry. In the 4-Wheeler segment, we supply 0.3 mm motor core to EV, and we are the first to do so.

We have also installed an MSP Press line capable of manufacturing 0.2 mm thickness stamping, making us the first in India to install such a technologically advanced high-end press.

Supply Capacity

50,000 tonnes/year

Have an Operational Facility in

Indonesia

A Strong Foothold at

Europe & Southeast Asia

Technological Investment

High-speed cutting lines

Our Product Offerings

Cut-to-size laminations, built-up cores, flux plates

CERO: Driving Sustainability, One Recycled Vehicle at a Time

At CERO, our name embodies our vision—derived from the Spanish word ‘CERO,’ meaning ‘Zero.’ We are dedicated to driving a future with zero waste, zero pollution, and zero dependence on imported metal scrap, ensuring a cleaner, more sustainable tomorrow.

Through CERO, India’s first authorised vehicle recycler, we are leading the transition towards responsible end-of-life vehicle (ELV) recycling. In collaboration with MSTC Limited (a Government of India enterprise), we have established 46 registered vehicle scrapping facilities and collection centres across the country, offering a seamless, technology-driven, and legally compliant scrapping experience.

A Hassle-free and Legal Recycling Process

CERO ensures a seamless and legally compliant recycling process through a structured, government-approved framework. From collection at authorised centres to systematic dismantling and recycling, every step is managed with precision. Customers receive legally valid documentation, including a Certificate of Deposit (CoD), ensuring transparency and compliance while also unlocking benefits on future vehicle purchases.

Lower Pollution

Reduces environmental impact through responsible vehicle scrapping

Seamless Compliance

Manages deregistration and regulatory paperwork effortlessly

Energy Efficiency

Uses 74% less energy to recycle steel compared to producing new steel

Financial Benefits

Unlocks incentives through CoD on new vehicle purchases

Conserving Resources

Minimises reliance on mining iron ore, coal, and other materials

Our Impact in FY 2024-25

11,669 Vehicles

Responsibly Recycled

10,400 Tonnes CO₂ Emissions

Reduced through ELV Recycling

7,300 Tonnes

Ferrous Scrap Recycled

11,600 Tonnes

Iron Ore Saved

Choosing CERO for vehicle recycling means making a responsible choice for a sustainable future!