- Chairman Message

- Managing Director

- Operational Excellence

- Digitisation

- Technology, Product & Process Innovation

the Chairman

Message from

Chairman’s Desk

As a company, we believe that growth is ingrained in our DNA, and we have consistently evolved over time. It gives me great pleasure and honour to announce a significant transformation and advancement in our Company’s identity. Drawing upon our rich heritage spanning 75 years, we have now rebranded from Mahindra Intertrade Limited to ‘Mahindra Accelo Limited’ (MAL).

Dear stakeholders,

I am thrilled to report that our Company has again delivered a stellar performance this year. Despite encountering various challenges, we registered record-breaking results, achieving the highest-ever revenue and volume. This performance is a testament to our dedication to innovation and our steadfast focus on technology. Our success would not have been possible without the resilience and commitment of our exceptional workforce. Together, we demonstrated a strong and agile business mindset, allowing us to navigate through turbulent times and emerge even stronger. With great pride, I commend our team for their remarkable efforts and for raising the bar for future accomplishments.

Over the years, our business models have evolved to serve various industries and expand our portfolio of products and services. All our offerings are oriented towards decarbonising industries in one way or another. Our efforts include improving steel efficiency, developing clean energy solutions utilising steel, and recycling steel waste, all driving us towards a carbon-neutral future.

Transforming for the Future: Evolution from Mahindra Intertrade to Mahindra Accelo

As a company, we believe that growth is ingrained in our DNA, and we have consistently evolved over time. It gives me great pleasure and honour to announce a significant transformation and advancement in our Company’s identity. Drawing upon our rich heritage spanning 75 years, we have now rebranded from Mahindra Intertrade Limited to ‘Mahindra Accelo Limited’ (MAL). We have progressed from our humble roots as a steel trading and processing company to becoming a leading ‘Mobility and Energy Components Company’. Our commitment to progress has enabled us to remain at the forefront of innovation and technology, and we look forward to continuing to serve our customers with the same level of excellence under our new identity.

A Fresh Perspective: Rebranding for Success

Over the years, our business models have evolved to serve various industries and expand our portfolio of products and services. All our offerings are oriented towards decarbonising industries in one way or another. Our efforts include improving steel efficiency, developing clean energy solutions utilising steel, and recycling steel waste, all driving us towards a carbon-neutral future.

With our Company having evolved over several decades, it has become increasingly important to realign our brand position to reflect both our current and future aspirations. Accordingly, we have transitioned to become a ‘Mobility and Energy Components Company’.

Achieving Excellence: Our Strong Performance

During the year, we achieved historical results by recording the highest-ever volumes and revenue. FY 2022-23 saw our volume and revenue grow by 27% and 37%, respectively, over the previous year. Our enhanced operational efficiency, robust manpower, customer-centric approach, acquisition of new customers, and innovative mindset have contributed to this achievement. Additionally, our plants are currently operating at optimal capacities. Building upon such record performance, we continue to enhance our capacities, invest in new technology, enhance people skills, and develop new products and services. All our businesses are focussed on providing cutting-edge technology to our customers with a strong emphasis on decarbonisation.

Driving Growth: Capability Building and Investment in the Future

At the heart of our Company’s culture lies our unwavering commitment to our RISE values, which drive us to innovate and work collaboratively towards our shared goals. We owe our success to our passionate employees, who are our greatest assets and the driving force behind our growth. Their focus on our Company’s goals has enabled us to achieve exceptional results and reach new heights. We are proud to have been ranked as the 3rd best mid-size company in the Great Places to Work awards. This recognition inspires us to dream bigger and strive harder for continued excellence.

We are currently operating our plants at optimal capacity utilisation. Last year, we invested in an advanced, fully automated Shearing line at our Kanhe (Pune) plant, which has proven to be a game-changer in our operations. Building on this success, we are now focussed on further enhancing our capabilities by investing in cutting-edge technologies such as a world-class high-speed Trapezoidal Line and Slitting line at our Chakan (Pune) plant. These strategic investments will allow us to expand our existing business and attract new customers by providing high-quality solutions with shorter lead times.

With an objective to constantly innovate and making our Company EV-ready, we have embarked upon our journey to become a Tier 0.5 Auto Component player.

Charting a Course: Our Vision for the Future

With a strong recovery post covid, the global economy faces recessionary pressures and high inflation. Central banks across the world are increasing interest rates to curb high inflation. This can impact short-term demand and increase volatility in commodity prices. While India is better positioned amongst the global economies to ride these uncertainties and will be one of the fastest-growing economies, we must be prepared to handle any challenges and surprises. The past few years have made our Company more resilient and prepared than ever before. I am very optimistic that our Company will continue to deliver strong results by focussing on technology, sustainable practices and high standards of Governance.

As we embark on a new chapter, I want to express gratitude to all our stakeholders for their continued trust, support, and confidence.

Warm regards,

Bharat Doshi

Chairman

During the year, we achieved historical results by recording the highest-ever volumes and revenue. FY 2022-23 saw our volume and revenue grow by 27% and 37%, respectively, over the previous year.

the Managing Director

Message from

Managing Director

I am privileged and pleased to announce that our Company has undergone a name change from Mahindra Intertrade Limited to Mahindra Accelo Limited (MAL). Growth is part of our DNA. From our humble beginnings as a steel trading company to the ‘Mobility and Energy Components Company’ we are today, we have never shied away from change when it is the right thing for our stakeholders.

Dear stakeholders,

The FY 2022-23 kicked off on a historical note for us for multiple reasons as in previous year, we registered record revenues and profits, were honoured with numerous accolades such as the Best Governed Company Award, secured the top 10 ranking in Great Place to Work , and achieved Stage 6 in our The Mahindra Way (TMW) journey. With these achievements, we have set the bar high for our goals in FY 2022-23.

Our unwavering commitment to ensuring a positive and enthusiastic work environment has led us to achieve a high rank of 3rd place in India’s Great Mid-size Workplaces, consistently maintaining a top 10 position over the past five years. This accomplishment would not have been possible without the dedication of our innovative and resilient workforce.

The Accelo family had an eventful year. First up, as the world slowly regained some sense of normalcy following the COVID-19 pandemic, we were thrilled to resume our work from the office while taking every possible precaution. For us, the year was marked by significant milestones driven by strong business momentum and an unwavering commitment to growth. Considering these achievements, I am delighted to present our Company’s Annual Report for FY 2022-23.

Building Resilience through Our Consistent and Strong Financial Performance

During the year under review, we delivered the highest-ever volumes amounting to 4,44,329 tonnes, up 27% y-o-y. We achieved the highest-ever revenue of ₹4,188.4 crore, up by 37% y-o-y. While our PAT decreased to ₹146.6 crore from ₹180.46 crore in the previous year, down by 19%, still it is ~3x over F21 PAT. The decrease in PAT was due to volatile commodity prices, a change in product mix, increase in depreciation and interest as we continue to invest in new technologies.

Evolution from Mahindra Intertrade to Mahindra Accelo to drive the Decarbonisation Revolution

I am privileged and pleased to announce that our Company has undergone a name change from Mahindra Intertrade Limited to Mahindra Accelo Limited (MAL). Growth is part of our DNA. From our humble beginnings as a steel trading company to the ‘Mobility and Energy Components Company’

we are today, we have never shied away from change when it is the right thing for our stakeholders. This evolution is the result of our continuous investment in world-class technology, dedication to creating sustainable products, addressing customer needs, and, most importantly, our people’s commitment to driving change.

We have undertaken a new branding exercise for our Group and have identified a new brand positioning – The Decarbonisation Revolution. This is because all our business segments contribute to decarbonisation in some capacity. We combine state-of-the-art technological advancements with a sustainability commitment to develop green solutions for a carbon-neutral future. In line with this vision, we initiated our journey of transitioning from being solely a steel processing company to becoming a prominent ‘Mobility and Energy Components Company’.

Putting Our People First

Our unwavering commitment to ensuring a positive and enthusiastic work environment has led us to achieve a high rank of 3rd place in India’s Great Mid-size Workplaces, consistently maintaining a top 10 position over the past five years. This accomplishment would not have been possible without the dedication of our innovative and resilient workforce. Additionally, we were also recognised as one of India’s Top 25 Manufacturing Companies and Top 25 in Building a Culture of Innovation by All, highlighting our efforts to foster a culture of creativity and excellence.

Business Performance

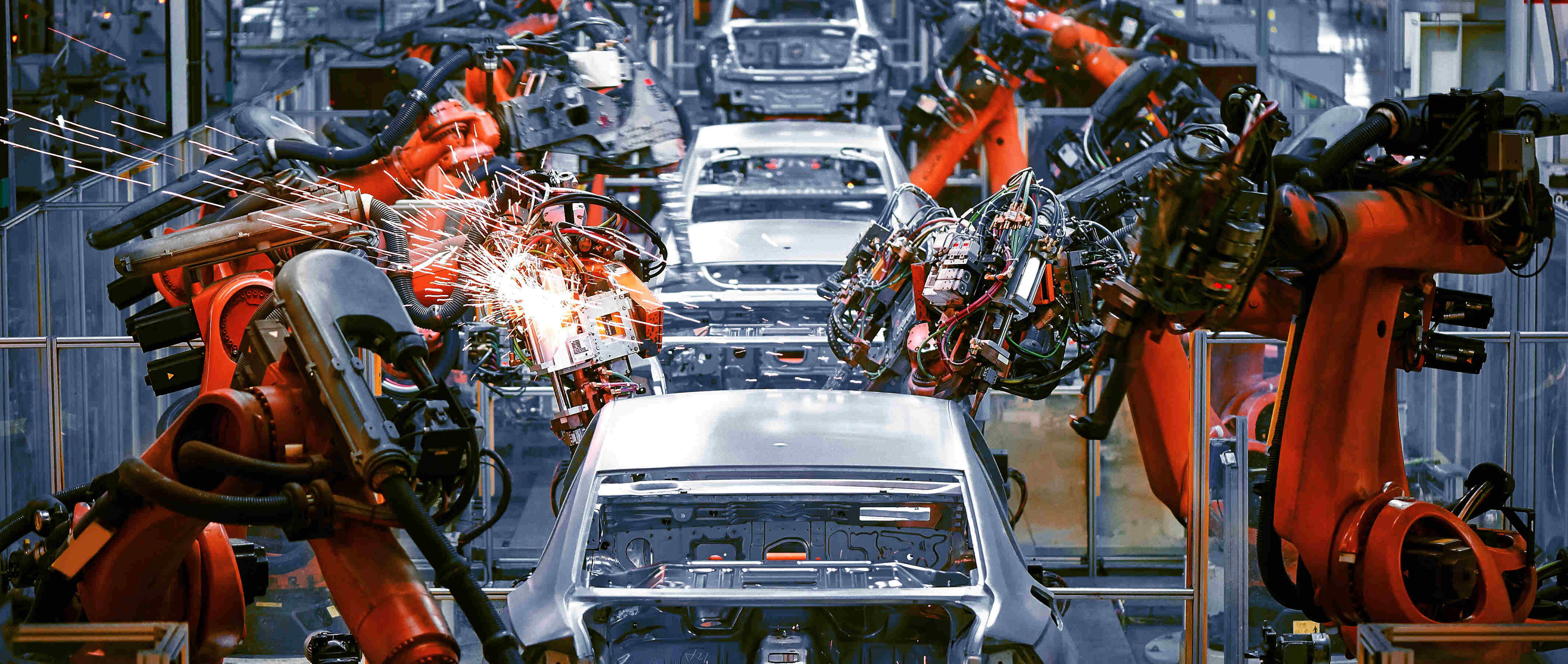

Mobility Segment – Automotive Business

During the year, we recorded our highest-ever automotive steel volumes. This historic performance was due to a strong growth in the volumes of Mahindra & Mahindra Limited (M&M) and increased share of business with existing customers. Our investment in new plants and technologically advanced lines are helping us expand our customer base.

Mobility Segment – Electric Vehicle Business

Our existing lines are equipped to manufacture BiW components for Electric Vehicles using Advanced High Strength Steel. We have also successfully developed the capability to supply motor cores for Electric three-wheelers and will begin supplying motor cores for four-wheeler EV & Hybrid vehicles starting this year. We have collaborated with global technology partners to create a high-end prototype for battery casings to be used in four-wheeler EVs.

Mobility Segment - Automotive Recycling (CERO) Business

CERO is India’s first organised automotive vehicle recycler. Last year, the Government of India launched the Voluntary Vehicle Scrappage Policy. Once all states implement this policy in right spirit, the inflow of end-of-life vehicle (ELV) to the organised recycling sector will grow exponentially. We have rapidly expanded our presence to 41 cities, with 9 registered vehicle-scrapping facilities and 32 collection centres as on FY2023.

Energy Segment - Power Business

With a focus on high-end components for transformers and a pan-India presence, we have maintained our leadership position in the power component space. We have 2 international plants at Sharjah and Indonesia, catering to global markets and exporting to 25+ countries. Our high-end components lead to low core losses during electricity transmission. We are ready to capture the renewable energy wave and be part of the sustainable growth journey of India.

Energy Segment - Electrical Stampings Business

With the technology to make highly efficient stators & rotors, we are India’s leading home appliance supplier. Our set-up showcases the best global technologies under one roof. This includes electrical stamping presses from Japan and Taiwan, die-casting lines from Italy and annealing lines from the USA. It is one of the few facilities in India to have a presence across the complete value chain from steel to stampings along with offering top quality Cold Rolled Non-Grain Oriented (CRNO) Steel to its customers.

Preparing for the Future: Strategies for Success

As the world increasingly focusses on sustainable, green solutions, we are committed to leading the way towards a more sustainable future. Our investment in world-class technology reflects this commitment. We aim to become a Tier 0.5 auto component player by investing in one of India’s first high-end tandem and transfer presses, capable of supplying skin panels and Class A/B components for both EVs and ICE vehicles. Furthermore, we are investing in high-end robotic welding lines for critical Class B assemblies, which will enable us to secure a leadership position in the EV component space. With the implementation of the vehicle scrappage policy, we plan to maintain our leadership position by being a first mover in the organised vehicle recycling space. With this, we want to support a circular economy by giving back steel and other components to respective manufacturers. With our strategic partnership to source high grade CRGO steel and ability to supply various value-added services/components, we continue to invest in technology and maintain a leadership position in the energy segment.

I express my sincere gratitude to our dedicated employees for their unwavering commitment and hard work, which have been instrumental in propelling us to new heights. I remain highly optimistic about the future and confident that with our steadfast commitment to sustainability, we will continue to exceed the expectations of all our stakeholders, while achieving even greater levels of success and growth.

Warm regards,

Sumit Issar

Managing Director

Sharpening our

operational edge

Delivering exceptional operational performance is essential to our long-term success. To accomplish this, we blend efficient personnel involvement with strategic use of Kaizen and Lean techniques, all under the guidance of a dedicated and knowledgeable leadership team. We take careful measures to enhance our abilities, ensuring we remain ahead of the competition.

Implementing the 6S Strategy

We have implemented the ‘6S’ strategy, which includes 5S and safety, across all our focus areas. We have divided each factory into zones with designated ownership, and there’s a 5S manual available. We conduct periodic red tag campaigns, and 6S is implemented in our shop floor, office areas, and even at our workers’ homes. Our efforts have created a conducive environment for achieving excellence within our factory premises. We conduct regular 5S audits, and the score is a part of the Balanced Score Card (BSC)/Key Result Area (KRA) for management staff. We are proud recipients of the 5S Excellence Trophy awarded by the CII.

Kaizen Journey

Our Company is committed to eliminating eight types of wastes (Mudas) by implementing Kaizen methodology. These include overproduction, waiting, motion, transportation, inventory, defects, over-processing, and unused skills. We have established an online Kaizen portal with a horizontal deployment feature to support this effort, enabling the successful replication of relevant Kaizens across different locations. Our coordinators evaluate and categorise Kaizens into levels I, II, and III, based on their impact on PQCDSHM (Productivity, Quality, Cost, Delivery, Safety, Health, and Morale), low investment, originality, root cause elimination, and other factors. We offer monetary awards for each location’s top three Kaizens per month, along with Kaizen certificates signed by our Vice President. Additionally, we recognise the location/employee with the most number of Kaizens at our annual Steel conference with the Kaizen Spark award. These recognitions serve to encourage a culture of Kaizen within our organisation.

Visual Factory

As part of our Total Productive Maintenance (TPM) efforts, we introduced visual control and management processes in all shop floors. To facilitate ease of understanding and compliance, we have converted all Standard Operating Procedures (SOPs) from English to local languages and have incorporated pictorial and video-based SOPs.

Total Productive Maintenance (TPM)

Our Company’s aim is to attain the ‘4 Zeros’ - Zero Accident, Zero Defect, Zero Waste, and Zero Breakdown - through the implementation of Total Productive Maintenance (TPM). This has resulted in significant improvements in Overall Equipment Effectiveness and in Productivity, Quality, Cost, Delivery, Safety, and Morale. By effectively implementing TPM, we have created a cultural shift from the traditional ‘I operate, You troubleshoot’ mindset to ‘I operate, I troubleshoot’ approach. Our Kanhe and Nashik plants have been certified for TPM Excellence, and we have initiated the certification process for our Bhopal and Vadodara plants. Following the successful attainment of ‘TPM Excellence’, our Nashik plant is now preparing for the ‘TPM Consistency’ award. We have also developed a roadmap for TPM certification across all our remaining plants.

Innovation-Led Progress

Mahindra Accelo Group strongly emphasises innovation, driven by our proprietary MIND™ (Mahindra INnovation methoD) approach. To enable the successful implementation of MIND™, our team received extensive training from a specialised team from M&M’s innovation cell. The training workshop included both theoretical and practical elements of innovation implementation. As a result of our focus on innovation, our submission for the Mahindra Innovation Award in FY 2022-23, titled ‘Job Height Measurement on Load’ using Linear Variable Differentiable Transformer (LVDT) at our Kanhe plant, was a finalist.

Six Sigma

In 2017, we embarked on our Six Sigma journey by providing our employees with a comprehensive nine-day training programme on Six Sigma theory. The training was based on the Six Sigma Green Belt module of the American Society for Quality (ASQ) syllabus and was designed to be rigorous and thorough. During the year under review, we trained four batches of employees from Kanhe, Bhopal, Chakan, Vadodara, and Nashik, with two batches at Chakan, one at Kanhe, and one at Vadodara.

3,020

Kaizens completed across all locations in FY 2022-23

100%

Participation obtained for Kaizen implementation

4

Innovation projects

completed

3

Innovation projects in-progress

124

Trained Green Belts since 2017

₹ 2.24 crore+

Cumulative savings

Strengthening Our Safety Culture

We have implemented The Mahindra Safety Way (TMSW) model, which is a comprehensive approach to safety at all of our Accelo plants. This model consists of 25 process parameters and 8 result parameters, as per the guidance of the Central Safety Council. As a result of our proactive safety approach, we had zero reportable and non-reportable accidents across all of our plants and locations in FY 2022-23. To monitor the safety of all employees, we have also implemented a departmental safety score methodology. Furthermore, all safety audits conducted thus far have not observed any serious or critical safety concerns.

ISO Certifications

All our plants are ISO 9001: 2015, ISO 14001: 2015 and ISO 45001: 2018 certified by TUV NORD, while our Chakan and Chennai plants are IATF 16949: 2016 certified. Kanhe plant completed the IATF assessment successfully by Bureau Veritas. These certifications have helped institutionalise robust processes and systems into our operations.

Value Stream Mapping (VSM)

We perform VSM by first calculating the Takt time, representing the customer demand time. Next, we map out the process from the supplier to the customer. During this process, we identify value-added and non-value-added activities and establish timelines for each. We then convert internal activities into external ones, while eliminating non-value-added activities. VSM projects were successfully implemented at both our shearing and die-casting lines, significantly improving our Process Cycle Efficiency (PCE). As a result, we enhanced our delivery performance in line with our customer requirements.

Single Minute Exchange of Die (SMED)

Our slitting lines have undergone successful SMED implementation. We utilised the Elimination, Combine, Realignment and Simplify (ECRS) principle to achieve this. As a result, we have significantly reduced the time taken to load and unload the die from several minutes to a single digit.

The Mahindra Way (TMW)

The Mahindra Group’s business excellence model The Mahindra Way (TMW) helps us to implement and promote comprehensive quality management through prioritised, systematic and continuous improvement, along with the application of Group Common Policies and Practices. In our pursuit of moving towards operational excellence, we have been promoted to Stage 6 in TMW Assessment. Very few companies across the Mahindra Group have been able to reach Stage 6.

Safety Audits Conducted

- TMSW by CSC assessors

- IS14489 by DISH-approved auditor

- ISO 45001 by TUV Nord

- Internal safety audits

Adopting digitisation

across the

value chain

We are committed to strengthening our digital platforms that improve the execution process for both our customers and internal operations. These platforms aim to enhance efficiency and convenience significantly for all stakeholders involved. Currently, we have several applications in place that serve critical functions, and we have several more in the pipeline set to launch in the coming year.

Digital roll-out dashboard

|

Stage

|

Operation & Supply Chain

|

Finance & Accounting

|

Human Resources

|

Other Processes & Reporting

|

Total

|

|---|---|---|---|---|---|

| Deployed | 27 | 11 | 1 | 4 | 43 |

| Under Development | 6 | 2 | 1 | 1 | 9 |

| Planned | 4 | 4 | 1 | 10 | |

| Total | 37 | 17 | 2 | 6 | 62 |

MRP Report

Need

The maintenance of raw material planning in an excel sheet has led to instances of excess or shortage of RM stock and numerous open purchase orders in the system.

Solution

We have recently introduced an MRP report that provides a comprehensive view of the status of raw materials, including MRP, GRN pending, stock at job workers, inventory, and indicators based on material MRP. With access to all the necessary details, open purchase orders can be closed on time, leading to better control over stocks.

Result

By achieving just-in-time stock with proper usage, we can effectively control overstocking. This leads to significant time savings in raw material planning, as we will only order the required amount of material when needed rather than ordering in bulk and storing excess inventory.

PDC Unlock Screen and PDC Details Uploading in SAP

Need

In the past, approvals were obtained manually and then had to be manually updated across individual invoices. This process also had to be replicated in PDC across all bills in SAP, which was time-consuming and caused delays. As a result, the sales team had to send approval request emails, resulting in trucks being held up.

Solution

We have developed an application that displays all data on one screen. When approved by the assigned approver, all invoices are unlocked within seconds. Additionally, PDC upload in SAP can now be done through an excel file.

Result

This new system has resulted in significant time savings-an estimated 3 minutes per transaction. This includes time saved on PDC approval, which previously amounted to 14 per day, and PDC updates, which amounted to 40 transactions.

Production Slitting Screen

Need

In the past, slitting calculations were done in Excel and manually transferred to the SAP system. Furthermore, the production process was not structured based on a Bill of Materials (BOM).

Solution

Our new system provides all the necessary checks and balances, ensuring input matches output. We can also easily calculate the required quantity based on the width entered, resulting in significant time savings. Furthermore, this screen is user-friendly and can be operated by machine operators as well.

Result

Implementing this new system has resulted in significant time savings, with an estimated 10 minutes saved per transaction, equating to approximately 1 minute per transaction, as we typically perform around 50 transactions daily.

Learning Management System (LMS)-SAP Integrations

Need

Previously, Vendor codes and Materials had to be created manually, which took approximately two days to complete for each vendor. PO/GR/Bill passing, we had to download all the relevant data into an Excel file and manually enter the information into the SAP system.

Solution

We have implemented a fully integrated system between the LMS (CERO Customer platform) and SAP using APIs. This system now includes automatic vendor and material creation, as well as automatic PO/GR/bill passing and advance payment processing.

Result

With the implementation of this fully integrated system, we have achieved significant time savings, with an estimated 10 minutes saved per transaction, which now takes approximately 1 minute to complete. Additionally, manual intervention is no longer needed, resulting in a much smoother and more streamlined process. We typically perform around 70 transactions per day, making this a significant improvement in efficiency.

Material Creation

Need

Previously, users had to manually create material codes one by one across all plants, which was both time-consuming and prone to errors.

Solution

With the implementation of this programme, we can now create up to 500 new materials in the system at once, resulting in significant time savings and significantly reducing the risk of errors.

Result

The implementation of this programme has resulted in significant time savings, with an estimated 20 minutes saved per transaction, which now takes approximately 1 minute to complete. We typically create around 30 new materials per day, making this a significant improvement in efficiency.

Invoicing (Delivery/PGI/Invoice in One Step)

Need

Previously, the process for completing this task involved three separate steps and also required manual input for batch placement, resulting in a time-consuming process.

Solution

Implementing this programme has resulted in a much more streamlined and efficient process for invoicing. Users can now enter all the relevant details for invoicing, including transport details, batch selection, and packing materials, all on a single screen. This information is then linked to the despatch screen, allowing for a continuous flow of information, resulting in significant time savings and significantly reducing the risk of errors.

Result

The implementation of this programme has resulted in significant time savings, with an estimated 10 minutes saved per transaction, which now takes approximately 1 minute to complete. As we perform approximately 1,300 transactions per day, this immensely improves efficiency. Having all the relevant data on a single screen has further improved our ability to process transactions quickly and accurately.

Hyperion Step Consolidation

Production Planning

By implementing MRP-based production planning, we can reduce manual efforts and minimise our dependency on manual labour. This helped us maintain a proper inventory of finished goods and restrict excess production above the maximum level defined in our SAP system. Ultimately, this will lead to a more streamlined and efficient production process, allowing us to better meet customer demands, while maximising our resources.

Production Declaration

With the introduction of an automated system for scrap entry, we can eliminate the need for manual calculations, including profile design scrap. This will significantly reduce errors in declaration entry in our SAP system, improving the accuracy of our records. We have further implemented the FG stick printing to streamline the process even further. A detailed analysis of data will be available for scrap reconciliation, enabling us to identify and address any actual or theoretical differences. This will lead to a more efficient and effective system for scrap management, saving time and reducing the risk of errors.

Result

By using this program, we can save around 5-6 minutes per coil declaration in SAP, which adds up to approximately 40 transactions per day.

Inventory App

Need

Stock take was previously done manually, where an SAP Excel dump was printed on paper and updated in an Excel sheet for reconciliation. This process took approximately two days to complete and required around 20 officers.

Solution

Developed an Inventory App that streamlines the stock take process. Using the app, one person can scan the QR code of each material, with the capacity to scan up to 900 materials in just one hour. The app also features an automatic reconciliation process, eliminating the need for manual updates on an Excel sheet. This saves time and reduces the number of officers needed for the stock take, making the process more efficient.

Result

Stock take reduced from 2 days to 1 hour (4 transactions per year across 10 plants) with the help of the Inventory App developed, which enables a single person to scan the QR code and conduct the stock take with auto reconciliation.

Robotic Process Automation (RPA)

Need

For some tractions, users had to generate reports periodically which was a repetitive and time-consuming job. It also created a dependency on specific individuals.

Solution

RPA or Robotic Process Automation is a technology that uses software robots to automate repetitive, rule-based tasks. Implementing RPA eliminates the need for manual intervention, reduces errors, and increases efficiency. In our organisation, we have developed various RPAs to automate the following processes:

1.Auto Stock/Despatch report: The system automatically triggers mails for this report, which helps us control inventory.

2.Vehicle-wise Analysis & Realisation Report: The executable RPA generates this report, providing detailed analysis and realisation of vehicle-wise data.

By implementing these RPAs, we have reduced the manual efforts and made the process more efficient. There is no dependency on any individual, and the reports are generated automatically, saving time and reducing errors.

Result

Implementation of RPA has helped us save 2 hours more daily/weekly.

Accelerating

technology-led progress

Innovation is at the core of our business, as we maintain an unwavering dedication to driving progress and pushing the boundaries of what is possible. We are passionate about leveraging the latest and most cutting-edge technologies to drive our endeavours forward, whether we are developing new products or finding ways to optimise our operations for maximum efficiency.

As we have grown and evolved, we have embraced a series of transitions, moving from trading to processing to creating value-added products. We remain focussed on leveraging technology to fuel our continued growth and success. With a team of dedicated innovators and a deep commitment to excellence, we are excited to see what the future holds and to continue pushing the boundaries in our industry.

Mobility Segment – Product-Led Growth

We are a dynamic and innovative Automotive steel supply chain player, constantly pushing boundaries and adapting to changing market needs. Our journey began as a steel coil supplier, but we have evolved into a high-end component supplier by investing in product development, world-class machinery, operational efficiency and a robust distribution model.

Our pioneering spirit led us to set up India’s first merchant blanking line in Nashik, marking our entry into the steel blanking/profiling segment. Recently, we achieved a milestone of supplying 1 MT of cumulative steel products from the Nashik plant alone. With a focus on technological advancement and sensing the trend towards thinner and stronger high-strength steel, we established India’s first servo blanking line at Chakan, the western auto hub of India. This facility can process steel up to 1,200 MPa and provides a launchpad for us to diversify into multiple product lines and OEMs.

Investing in state-of-the-art Progressive Stampings with a new high strength 1,500 tonnes progressive press line at Chakan has helped us acquire new OEM customers and become a Tier-1 supplier to OEMs. Our latest plant for Automotive steel at Chennai has further increased our non-M&M customer base, with its innovative product mix and high tensile processing capability. Our machinery can process high-tensile steel, which is in demand in the market.

Our aim is to become a Tier 0.5 auto component player and to achieve this, we are investing in one of India’s first high-end tandem and transfer presses. These presses can supply skin panels and Class A/B critical components for both EVs and ICE four-wheelers. Our investment in these lines will help us gain more share of business from existing customers and gain entry into automotive OEMs. These lines can also process Aluminium, which makes us ready for the EV revolution.

We are a forward-thinking player in the industry, and as such, we are one of the first auto component players in India to develop fully automatic robotic laser welding lines with Automated Guided Vehicles (AGVs). With these welding lines, we can supply critical assemblies to Automotive OEMs for EVs and ICE.

We have invested significantly in product development to cater to the EV component industry in anticipation of the growing demand for EVs. One of our major breakthroughs in this journey is the development of EV battery enclosures. We have also expanded our capabilities beyond steel to supply EV battery enclosure components in Aluminium, which is crucial for light-weighting, a requirement for the EV industry. With tie-ups with global leaders in various Aluminium processing operations like Stamping, Forming, Welding, Deburring, Cleaning, and Inspection, we have successfully supplied prototypes for EV battery enclosures. All our upcoming stamping lines will be capable of processing Aluminium, demonstrating our commitment to fulfilling changing customer requirements.

Mobility Segment – CERO – Unique Growth Model

We established CERO as India’s first Government-authorised vehicle recycler, investing heavily in setting up our first recycling facility in Greater Noida with imported machinery. However, due to the delay in announcing and implementing the scrappage policy in India, we needed to implement an innovative growth model for CERO.

Through the indigenisation of equipment to reduce capital expenditure and leveraging the Mahindra Group synergy, we were able to expand CERO’s presence across the country, increasing its customer touchpoints from 22 locations to 41 locations in FY 2022-23. Today, we have 41 customer touchpoints and plan to expand to 75+ within the next couple of years.

With the recent announcement of the scrappage policy by the Government of India and our low-cost innovative expansion model, we anticipate exponential growth in the recycling business segment in the coming years.

Energy Segment – Power - Innovation-Led Geographical Expansion and Customer Acquisition

Our innovative product mix in the Electrical steel segment (CRGO) is helping us expand our market presence while minimising costs. We offer cut-to-size laminations and value-added products such as built-up cores and flux plates, which help us attract a wider range of customers, particularly transformer manufacturers, who can focus on their core business and save on inventory/storage costs. Our investment in high-speed lines that can cut complete transfer logs simultaneously has enabled us to enter new markets, particularly in Europe where there is high demand for our products. We have world-class machinery for electrical steel components that only a handful of companies in India possess, allowing us to process high-grade CRGO steel. As market leaders in this space with a total capacity to supply around 50,000 tonnes per year, we are well-positioned for growth. Furthermore, our latest state-of-the-art facility in Indonesia offers a wide array of products and will help us gain a stronghold in Southeast Asia.

Energy Segment - Electrical Stampings – Entering New Market Segments

Initially, we began our journey in the electrical stampings business by supplying stators and rotors for electrical motors used in the Home Appliances segment. However, our innovative thinking enabled us to leverage the same investments and machinery to enter the Electric Vehicle segment. Today, this segment is one of the most important growth drivers for MAL, with the ability to cater to the growing Home Appliances and Electric Vehicles industry.

Currently, we can supply motor cores and even completely built-up EV motors to our customers. We are continually expanding our product offerings and engaging in discussions with multiple global companies to move up the value chain in the Electric motors segment.

Our commitment to quality and value addition to our customers is demonstrated by our recent selection as a supplier of motor cores to one of the world’s largest EV motor manufacturers for domestic consumption and exports to European markets. At present, we supply motor cores and stampings to the electric three-wheelers and four-wheelers..