Ready with

new zeal

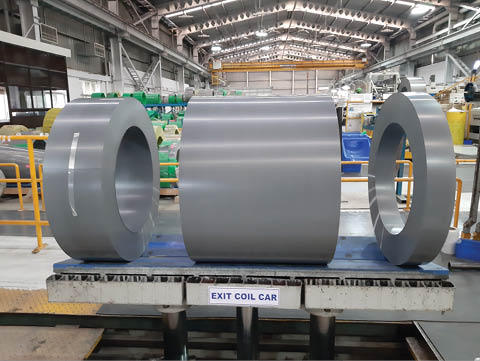

Mahindra Accelo is one of the oldest businesses within the Mahindra Group. Over the years, we have diversified our operations from a steel trading and processing business to high-end component manufacturing business.

Our focus has been engaging with the Automobile, EV, Power, and Home appliances sectors along with our new age business, vehicle recycling. We have realigned our offering across mobility and energy verticals to continue our growth story. We are constantly striving to provide the best services possible to our clients, and we are expanding into new geographies.

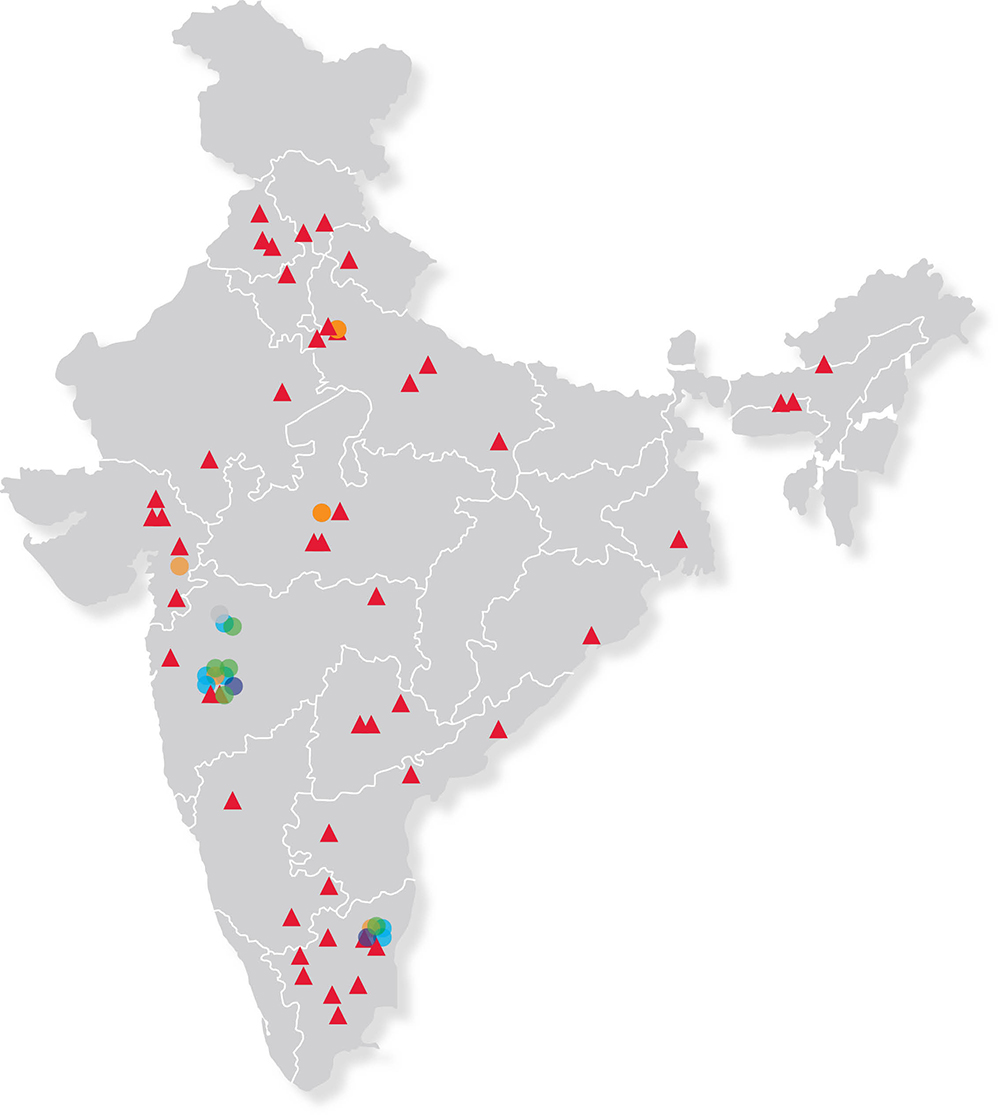

Over the years, our strategic partnership with global steel mills and trading conglomerates has enabled us to establish numerous group companies in different geographies. Currently, we have our presence in 10 locations, including plants at Pune (3), Nashik, Vadodara, Bhopal, Noida, and Chennai in India, as well as in Sharjah (UAE) and Indonesia. Additionally, we operate Registered Vehicle Scrapping Facilities (RVSF) at 9 locations in India along with 32 CERO collection centres, for our vehicle recycling business.

Purpose

Drive positive change in the lives of our communities. Only when we enable others to rise will we rise #TogetherWeRise

Core Value

-

Professionalism

-

Good Corporate Citizenship

-

Customer First

-

Quality Focus

-

Dignity of the Individual

Best

Rank in Best Governed Company (Unlisted)

World of Accelo

Largest

Supplier of electrical steel components in India

1st

Steel service centre in India to be awarded ZWL certificate

1st

& Largest Government-authorised vehicle recycler in India

2+

Million tonnes of steel handled

19

State-of-the-art facilities globally

2

Plants are TPM* certified

41

Cities covered through auto recycling (CERO)

25+

Countries where we export our products

4.30

MCARES score (2023)

95

Customer Satisfaction Index score (2022-23)

3rd

Among great mid-size workplaces by Great Place to Work® in 2022

Top 25

Best Workplaces in Manufacturing 2022 & Best Workplaces in Building a Culture of Innovation for All

* TPM – Total Productive Maintenance

All our firsts

1st

Steel service centre in India in the organised sector

1st

Electrical steel service centre in South Asia

1st

Steel service centre abroad by an Indian entity

1st

Vehicle recycling facility in India in the organised space

Rise for a More Equal World

Climate Change, Inclusion, Ethics

Rise to be Future Ready

Customer-Focussed, Technology, Innovation

Rise to Create Value

Entrepreneurship, Scale, Impact

Progressing with

focus and foresight

Nations rise when their mobility and energy sectors grow. We help key industries advance by supplying high-end components and reducing their use of resources. By prioritising sustainability, we help key industries advance and promote economic and environmental sustainability.

Mobility

Mobility rises with Accelo

The world is moving ahead on automobiles. The automobile sector moves ahead by using our high-end sustainable components.

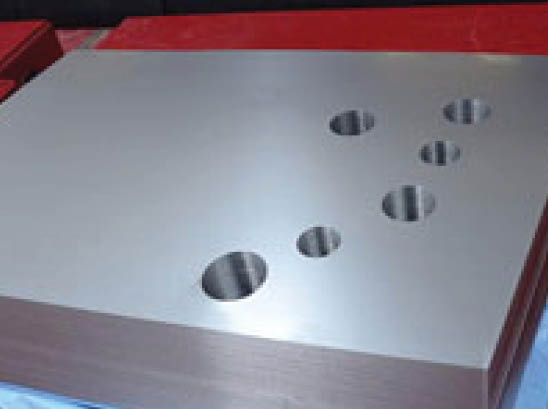

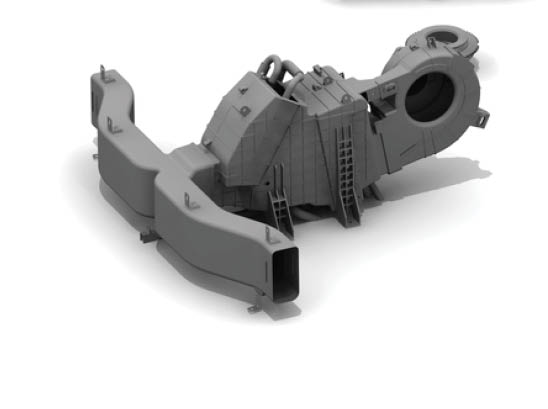

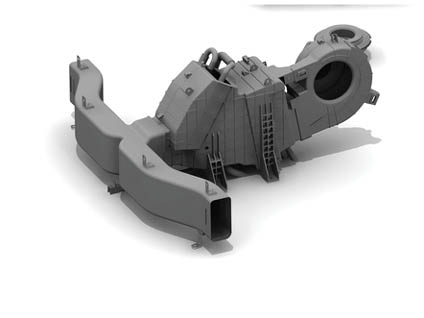

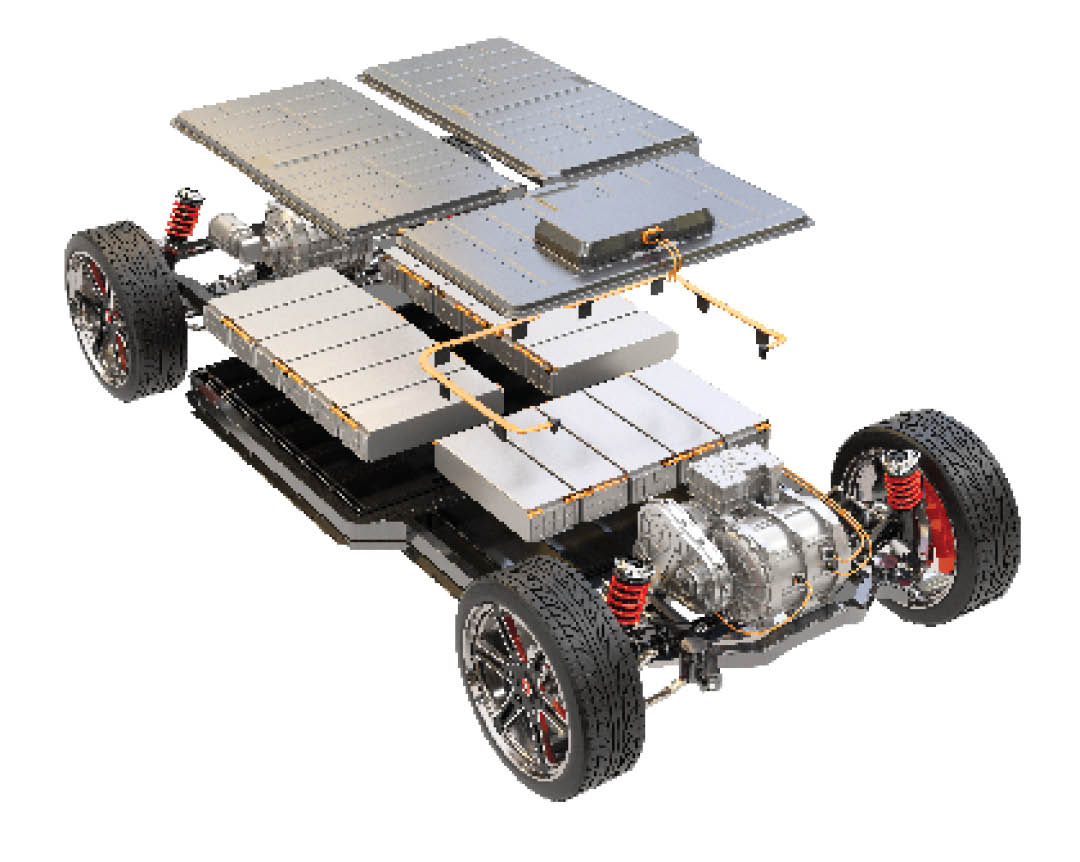

We utilise advanced technology for providing high-end BiW components using our blanking lines and India’s first high-speed progressive stampings. Our products are supplied to major automotive OEMs and are produced from four locations across India. As the automotive industry shifts towards electric vehicles (EVs), we have expanded our offerings to include supplying BiW components, motor cores (stator and rotor), and soon, aluminum battery casings & motors for EVs. We are consistently moving up the value chain from a steel processor to a high-end value-added component maker.

CERO, India’s first and largest Government-authorised scrapper of motor vehicles, is named after the Spanish word for ‘zero’. CERO aims to promote zero tolerance towards pollution, and unsafe and illegal practices while recycling vehicles.

-

Automotive

-

Electric Vehicle

-

CERO Recycling

Automotive

As a leading supplier of components for the automotive industry, we pride ourselves on utilising advanced high-strength steel to manufacture critical components that make today’s vehicles lightweight, safer, and more fuel-efficient.

Slitting

Blanking/Profiling

Shearing

Progressive Stampings

Class A Components

Class B Components

Assemblies

Electric Vehicle

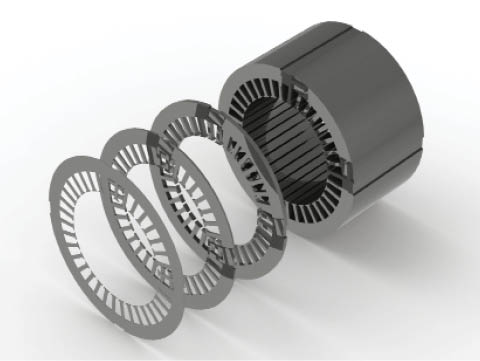

Our commitment to innovation and quality has enabled us to offer a wide range of solutions that meet the evolving needs of the EV industry.

Motor Cores

Class A Components

EV Battery Casing

Assemblies

Class B Components

CERO Recycling

CERO operates with 32 collection centres and 9 Registered Vehicle Scrapping Facilities across 41 cities in India. Thus offering an efficient way to recycle vehicles and obtain quality steel. This approach helps conserve valuable natural resources like iron ore, coal, and water, while reducing India’s dependence on imported scrap steel.

Cars

Trucks and Buses

Two-Wheelers, Three-Wheelers

Industrial Scrap

State-of-the-Art Facilities

Nashik

India’s 1st merchant blanking line offering products like Blanks and Profiles.

Kanhe I (Pune)

The facility possesses capabilities like Automotive (HR/CR) - Slitting, Shearing, Cut-to-Length Sheets.

Chakan (Pune)

The facility features India’s 1st high-speed progressive stampings line and an advanced blanking line capable of processing high-strength steel. The facility offers products like - Stampings, Blanks and Profiles.

Chennai

A high-end blanking line offering products like Blanks and Profiles.

Nashik

India’s 1st merchant blanking line offering products like Blanks and Profiles.

Kanhe I (Pune)

The facility possesses capabilities like Automotive (HR/CR) - Slitting, Shearing, Cut-to-Length Sheets.

Kanhe II (Pune)

The facility hosts state-of-the-art presses which manufacture high-end EV Motor Cores

Chakan (Pune)

The facility features India’s 1st high-speed progressive stampings line and an advanced blanking line, capable of processing high-strength steel. The facility offers the following products - Stampings, Blanks and Profiles

Chennai

A high-end blanking line, offering the following products - Blanks and Profiles

Greater Noida, Chennai, Pune, Ahmedabad, Indore, Hyderabad, Chandigarh, Guwahati & Bengaluru

Established presence in key cities with more than 1 million vehicle population by installing state-of-the-art equipment to depollute and dismantle any type of vehicle and industrial scrap, among others.

We have set up collection centres in major cities for collecting end-of-life vehicle scrap and transport it to the nearest RVSFs for recycling.

Progressing with

focus and foresight

Energy

Building Energy, Part by Part

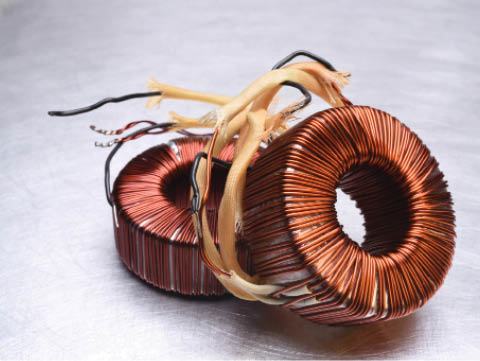

The energy sector consumes fewer resources by using our high-end components, made from the world’s best and most efficient electrical steel (CRGO).

We specialise in manufacturing components for the energy sector using the most efficient electrical steel available, CRGO. Our facilities are in 7 locations across India, UAE, and Indonesia.

Our extensive product portfolio includes slittings, laminations, built cores, flux plates, and core coil assembly for Power & Distribution Transformers. These products are exported to over 25 countries worldwide. Through our commitment to consistently processing high-grade electrical steel, we reduce losses in transmission, thus saving significant natural resources.

Our expertise in slitting, stamping, steam bluing, ultrasonic cleaning, welding, and CNC machining has also allowed us to become a leading player in supplying stators and rotors to AC compressors and fan manufacturers. Thereby extending our efficiency-boosting approach to the home appliances sector.

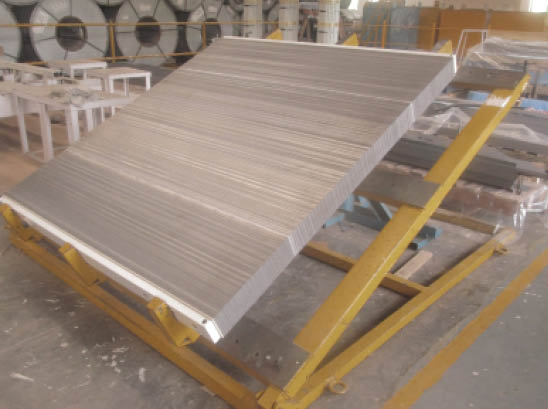

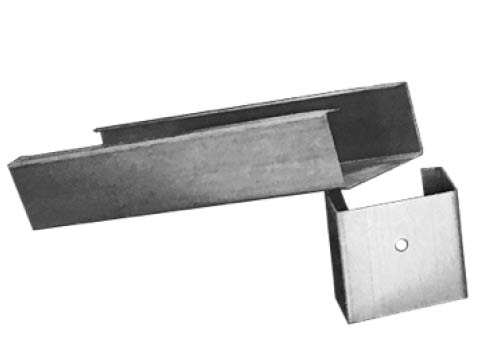

As the world moves towards renewable energy sources, we at Mahindra Accelo have expanded our offerings to include the supply of purlins or steel structures used for mounting solar panels on rooftops or ground level. By providing these components, we are contributing to the global shift towards green energy and decarbonisation of our planet. We take pride in being a part of this critical transition towards a sustainable future.

-

Power

-

Electrical Stampings

-

Purlins

Power

As India’s leading supplier of power components, we specialise in manufacturing high-grade components for transformers that significantly reduce transmission losses. Our power components are exported to over 25 countries worldwide.

Slitting

Lamination Core

Stacks

Built Up Cores

Core Coil Assembly

Flux Plate

Electrical Stampings

We are India’s leading home appliance supplier with the technology to make highly efficient stators & rotors.

Slitting

Electrical Stamping

Stators &

Rotors

Winding

Purlins

We are proud to contribute to the global shift towards renewable energy by supplying high-quality steel structures, or purlins, used for mounting solar panels on rooftops or ground level. Our purlins are designed to consume less steel, making them an efficient and eco-friendly option for solar energy installations.

1. C Type Purlin (c+,c++)

2. Z Type Purlin (z+,z++)

Manufacturing Facilities

Vadodara

Offers the following products and services - Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Bhopal

Offers the following products and services - Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Noida

Delivers the following products and services - Transformer Lamination Core Stacks, Built Up Transformer Cores

Kanhe I (Pune)

Offers the following products and services - Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Chennai

Offers the following products and services - Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Sharjah, UAE

Offers the following products – Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Indonesia

Offers the following products – Slitting, Transformer Lamination Core Stacks, Built Up Transformer Cores

Kanhe II (Pune)

Offers the following products and services - Slitting, Stamping, Stators & Rotors, Die casting, Heat Treatment, Motor cores

Chennai

The facility can do slitting of CRNO coils

Nashik

Offers C type & Z type purlins for solar industry

Growing our

prominence

We are committed to advancing our operations in India and across the globe to serve our customers better and contribute to the decarbonisation growth story.

- Mobility - Automotive

- Mobility - EV

- Mobility - Vehicle Recycling (CERO)

- Energy - Power

- Energy - Stampings

- Energy - Purlins

Disclaimer: This map is a generalised illustration only for the ease of the reader to understand the locations, and it is not intended to be used for reference purposes. The representation of political boundaries and the names of geographical features/states do not necessarily reflect the actual position. The Company or any of its directors, officers or employees, cannot be held responsible for any misuse or misinterpretation of any information or design thereof. The Company does not warrant or represent any kind in connection to its accuracy or completeness.

Loving our

journey

Backed by the rich legacy of the Mahindra Group, we have continued to strategically expand our operations, unlocking new growth avenues and strengthening our foundations with each passing year.

Mahindra Group was formed with first business being of Steel Trading

KANHE I

Set up 1st steel service centre in the organised sector in India catering to the automotive, home appliance and power sectors

SHARJAH

Set up the 1st steel service centre by an Indian corporate overseas, and 1st such facility in the region

BHOPAL

Set up an electrical steel service centre at Bhopal

VADODARA

Set up an electrical steel service centre at Vadodara

NASHIK

Set up 1st independent facility of a merchant blanking line for automotive skin panels in India

KANHE II

Entered a new vertical of electrical stampings, creating presence across the entire value chain, from steel slitting to stampings

CHAKAN

Set up India’s first high tensile servo automotive steel blanking line at Chakan

VADODARA

Expanded capacity at Vadodara with the installation of another lamination line

VADODARA

Expanded capacity at Vadodara with the installation of the 3rd lamination line, focussing on DT customers

NOIDA

Set up an electrical steel service centre for distribution transformer (DT) segment

BHOPAL

Expanded capacity at Bhopal with the installation of another lamination line, focussing on DT customers

NOIDA

Formed a JV with MSTC (GoI enterprise) , to set up CERO – India’s 1st Government authorised vehicle recycler

CHENNAI

Set up an integrated (Automotive and Electrical) steel service centre in Chennai to strengthen the business and presence in South India

CHENNAI & PUNE

Set up two new RVSFs at Chennai and Pune to recycle ELVs

AHMEDABAD, BANGALORE, CHANDIGARH, HYDERABAD, JAIPUR & MUMBAI

Set up collection centres for collecting & feeding ELVs to RVSFs for recycling

CHAKAN

Set up India’s 1st high-speed progressive stampings line with the capability to process High Tensile Steel, up to 1,200 MPa grade

CHANDIGARH, GUWAHATI AND BENGALURU

Set up three RVSFs to recycle ELVs

AMRITSAR, ANANTAPUR, BHUBANESHWAR, DEHRADUN, HUBLI, ITANAGAR, JALANDHAR, KANPUR, LUCKNOW, LUDHIANA, MANGALORE, MYSURU, NAGPUR, PATIALA, SALEM, SHILLONG, SHIMLA AND VARANASI

INDONESIA

Set up 2nd overseas steel service centre in Indonesia to cater to the power and distribution transformer industry

AHMEDABAD, INDORE & HYDERABAD

Set up three RVSFs to recycle ELVs

BHOPAL, COIMBATORE, GANDHINAGAR, KOLKATA, MADHURAI, SURAT, TRICHY, UDAIPUR, VADODARA, VIJAYAWADA, VIZAG, WARANGAL

Set up 12 collection centres for collecting and transporting ELVs to RVSFs for recycling

Mahindra Group was formed with first business being of Steel Trading

KANHE I

Set up 1st steel service centre in the organised sector in India catering to the automotive, home appliance and power sectors

SHARJAH

Set up the 1st steel service centre by an Indian corporate overseas, and 1st such facility in the region

NASHIK

Set up 1st independent facility of a merchant blanking line for automotive skin panels in India

VADODARA

Set up an electrical steel service centre at Vadodara

BHOPAL

Set up an electrical steel service centre at Bhopal

KANHE II

Entered a new vertical of electrical stampings, creating presence across the entire value chain, from steel slitting to stampings

CHAKAN

Set up India’s first high tensile servo automotive steel blanking line at Chakan

VADODARA

Expanded capacity at Vadodara with the installation of another lamination line

NOIDA

Set up an electrical steel service centre for distribution transformer (DT) segment

BHOPAL

Expanded capacity at Bhopal with the installation of another lamination line, focussing on DT customers

NOIDA

Formed a JV with MSTC (GoI enterprise) , to set up CERO – India’s 1st Government authorised vehicle recycler

VADODARA

Expanded capacity at Vadodara with the installation of the 3rd lamination line, focussing on DT customers

CHENNAI

Set up an integrated (Automotive and Electrical) steel service centre in Chennai to strengthen the business and presence in South India

CHENNAI & PUNE

Set up two new RVSFs at Chennai and Pune to recycle ELVs

AHMEDABAD, BANGALORE, CHANDIGARH, HYDERABAD, JAIPUR & MUMBAI

Set up collection centres for collecting & feeding ELVs to RVSFs for recycling

CHAKAN

Set up India’s 1st high-speed progressive stampings line with the capability to process High Tensile Steel, up to 1,200 MPa grade

INDONESIA

Set up 2nd overseas steel service centre in Indonesia to cater to the power and distribution transformer industry

AHMEDABAD, INDORE & HYDERABAD

Set up three RVSFs to recycle ELVs

BHOPAL, COIMBATORE, GANDHINAGAR, KOLKATA, MADHURAI, SURAT, TRICHY, UDAIPUR, VADODARA, VIJAYAWADA, VIZAG, WARANGAL

Set up 12 collection centres for collecting and transporting ELVs to RVSFs for recycling

CHANDIGARH, GUWAHATI AND BENGALURU

Set up three RVSFs to recycle ELVs

AMRITSAR, ANANTAPUR, BHUBANESHWAR, DEHRADUN, HUBLI, ITANAGAR, JALANDHAR, KANPUR, LUCKNOW, LUDHIANA, MANGALORE, MYSURU, NAGPUR, PATIALA, SALEM, SHILLONG, SHIMLA AND VARANASI

#TogetherWeRise

Trekking for a Purpose

Care of Nature

Yogesh Shirsat, who holds the position of Head of Operations at the Nashik Plant, is an avid trekker. He has passed on his love for nature to his daughter, Kavya, who has been accompanying him on treks since the tender age of 3.5 years. Thanks to this shared passion, Kavya has gone on to achieve great feats.

Kavya’s impressive trekking skills have earned her the prestigious Kantijyoti Savitribai Phule Award for successfully completing a trek through the challenging Sahyadri Forts. Kavya has completed a total of 28 forts in Maharashtra, including difficult ones such as Harishchandra Gad, Harihar, Prabal Gad, and Tirgalwadi, among others. Kavya has also completed a range trek from Panhalgad to Vishalgad twice, covering a distance of 64 km in three days, and a night trek from Bhimashankar to Bhorgiri, covering 34 km in just two days.

She had completed Kalsubai Peak (The highest peak of Maharashtra 5600ft) trek at the age of 7. She had repeated this trek on Women’s Day 2023 this year & was awarded by local organisation for same.

Through nurturing Kavya’s love for nature and instilling in her the importance of environmental conservation, Yogesh Shirsat has demonstrated that he Rises for an equal world #Together we Rise.

Driving Inclusion

Sharing Knowledge with Students

Narayan Dharmadhikari, the Chief of BE in Corporate Quality & Safety, believes in sharing his extensive knowledge and industry experience with the younger generation. Through his practical insights as an industry veteran, he has been able to provide valuable guidance to many aspiring students.

Furthermore, Narayan has taken up the mantle of spreading awareness about global climate change to adjacent industries. He has conducted sessions on science-based targets, the Paris agreement, the scope of emissions, and best practices for decarbonisation at MAL. He has also presented multiple papers on Green Supply Chain, including a presentation at INSSAN (Indian National Suggestion Schemes Association), New Delhi, and the 64th Annual National Convention of the Indian Institution of Industrial Engineering (IIIE) at Pune.

Narayan’s actions embody inclusivity, and he drives positive change through his knowledge-sharing and learning initiatives. By doing so, he Rises for a more equal world #Together we Rise.