Revolutionising Mobility

and Energy with Our

Product Spectrum

At Mahindra Accelo, we are driving the decarbonisation revolution with our innovative solutions in the Mobility and Energy sectors. We combine cutting-edge technological innovation with our commitment towards sustainability to create efficient green solutions for a carbon-neutral future. In the Mobility segment, this combination is pivotal to the world’s advancement in automobiles, offering high-end sustainable components that drive progress in the Automotive sector. Similarly, when it comes to the Energy sector, the world relies on energy, as it contributes by providing critical components and structures that reduce energy loss, enabling advancement in this crucial industry.

At Mahindra Accelo, we are driving the decarbonisation revolution with our innovative solutions in the Mobility and Energy sectors. We combine cutting-edge technological innovation with our commitment towards sustainability to create efficient green solutions for a carbon-neutral future. In the Mobility segment, this combination is pivotal to the world’s advancement in automobiles, offering high-end sustainable components that drive progress in the Automotive sector. Similarly, when it comes to the Energy sector, the world relies on energy, as it contributes by providing critical components and structures that reduce energy loss, enabling advancement in this crucial industry.

Mobility

Mobility

The automotive industry is advancing rapidly, and our high-end sustainable components play a crucial role in its progress. Leveraging advanced technology, such as cutting-edge blanking lines and India’s first high-speed progressive stampings, we specialise in providing top-notch Body-in-White (BiW) components. We have invested in world-class lines and robots which can manufacture skin panels, class B components and assemblies for EV/ICE 4-wheelers.

As the automotive sector transitions towards electric vehicles (EVs), we have expanded our offerings to include BiW components and motor cores (stator and rotor). Also, we will soon include aluminium battery casings for EVs in our portfolio. This diversification reflects our commitment to staying at the forefront of industry trends and effectively meeting the evolving needs of our customers.

Furthermore, we are consistently ascending the value chain, transitioning from a steel processor to a manufacturer of high-end value-added components. This strategic evolution highlights our dedication to introduce innovation and uphold excellence throughout our operations.

In addition, we are proud to be associated with CERO, India’s first and largest Government-authorised recycler of motor vehicles. The name ‘CERO,’ derived from the Spanish word for ‘zero,’ symbolises our commitment to promoting zero-tolerance towards pollution and unsafe or illegal practices in vehicle recycling. Through CERO, we strive to contribute to a cleaner, safer, and more sustainable future for all.

Automotive

Automotive

As a premier supplier of automotive components, we take pride in using advanced high-strength steel to craft critical components. These contribute to making modern vehicles lightweight, safer, and more fuel-efficient.

What We Offer

Slitting

Blanking/Profiling

Shearing

Progressive Stamping

Skin Panels / Class A Components

Class B Components

Assemblies

Our Capabilities

We are India’s leading EV/ICE automotive components supplier, equipped with state-of-the-art facilities across our production centres. Our capabilities include a G1 tandem line, a 3000 ton transfer press, a 1500 ton progressive press, blanking lines capable of aluminium stampings, and fully automated robotic welding lines. These advanced facilities enable us to meet the evolving needs of the automotive industry with precision and efficiency.

Our USPs

-

State-of-the-Art Manufacturing Facilities

Our facilities are equipped with cutting-edge technology, ensuring efficient and high-quality production processes.

-

Efficient Supply Chain Management

Our manufacturing and operational excellence has helped us deliver quality products on time to our customers, making us one of the preferred suppliers to OEMs.

-

Dominant Presence in West & South India

Our established presence in key regions like West and South India strategically positions us to effectively serve the growing automotive markets in these areas.

Nashik

Is home to India’s first merchant blanking line, offering products such as Blanks and Profiles.

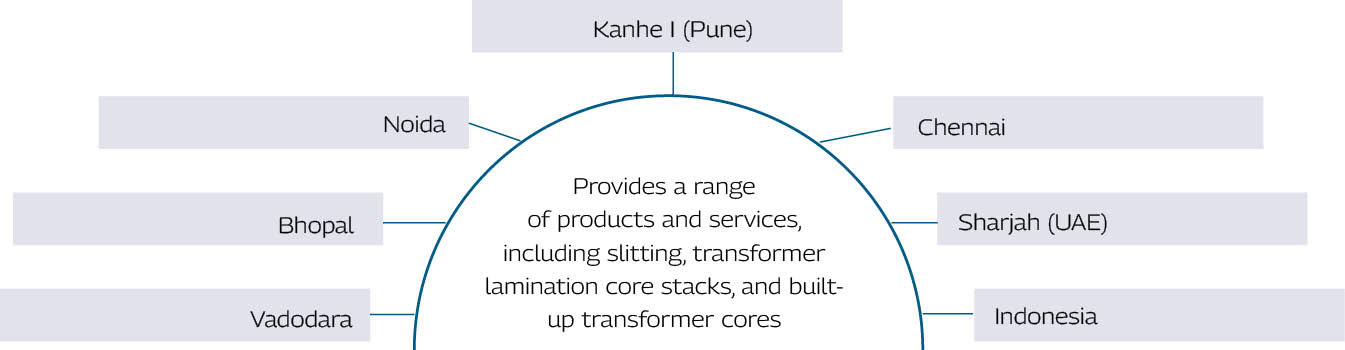

Kanhe I (Pune)

Is equipped with capabilities like Automotive (HR/CR) Slitting, Shearing, and Cut-to-Length sheets.

Chakan I & II (Pune)

Features India’s first 3,000 ton transfer press line, robotic welding lines, high-speed progressive stampings line and an advanced blanking line capable of processing High-Strength Steel. Offers products like Assemblies, Class B Components, Stampings, Blanks, and Profiles.

Chennai

Houses a high-end blanking line offering products like Blanks and Profiles.

Supa

Houses a world-class tandem press line offering products like Skin Panels / Class A Components

Electric Vehicles

Electric Vehicles

Our dedication to innovation and quality has empowered us to deliver diverse solutions that address the evolving requirements of the EV industry.

What We Offer

Motor Cores

Class A Components

EV Battery Casing

Assemblies

Class B Components

Our Capabilities

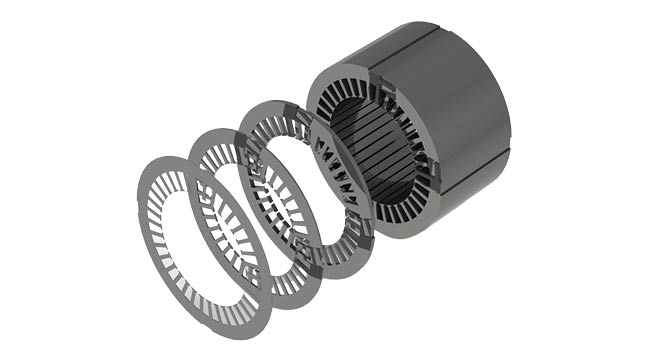

As a prominent player in India’s electrical stamping industry, we specialise in manufacturing motor cores for EVs (2-wheeler, 3-wheeler, 4-wheeler) and consumer durables. Our state-of-the-art facility is equipped to handle multi-row carbide dies, with rotation of each stamping and hydraulic backup pressure, enabling us to manufacture EV motor cores up to 0.2 mm thick.

Nashik

Is home to India’s first merchant blanking line, offering products like Blanks and Profiles.

Chakan I & II (Pune)

Features India’s first 3,000 ton transfer press line, robotic welding lines, high-speed progressive stampings line and an advanced blanking line capable of processing high-strength steel. Offers products like Assemblies, Class B Components, Stampings, Blanks, and Profiles.

Kanhe I (Pune)

Is equipped with capabilities for Automotive (HR/CR) - Slitting, Shearing, and Cut-to-Length Sheets.

Chennai

Operates a high-end blanking line, offering products like Blanks and Profiles.

Kanhe II (Pune)

Hosts state-of-the-art presses manufacturing high-end EV Motor Cores.

Supa

Houses a world-class tandem press line, offering products like Skin Panels / Class A components

CERO Recycling

CERO Recycling

Aiming towards a zero-pollution nation, CERO embodies the principles of zero-pollution, wastage, and dependence on metal scrap imports. It is India’s first organised vehicle-recycling unit and offers a hassle-free solution for recycling any vehicle, ensuring the best price for the scrap. With 42 collection centres and 7 registered vehicle scrapping facilities across India, CERO provides an efficient way to recycle vehicles and obtain quality steel. This approach contributes to conserving valuable natural resources like iron ore, coal, and water, while reducing India’s reliance on imported scrap steel.

We purchase and recycle vehicles regardless of their condition

Cars

Trucks and Buses

Accidental Cars

Industrial Scrap

2-Wheelers/3-Wheelers

Tractors

Our USPs

-

Strategic Partnerships with Leading Automotive Companies

CERO has partnered with Mahindra & Mahindra Limited, Renault India, and Daimler as key partners for their vehicle exchange and scrap programmes across India, showcasing trust and reliability in the industry. CERO has also partnered with Jubilant FoodWorks to scrap their ELVs.

-

Investment in Technology

CERO is committed to promoting innovation and maintaining sustainability. To that end, it has developed a world-class Lead Management System (LMS) to streamline operations and enhance efficiency in vehicle recycling process.

-

Nationwide Presence

With a presence in 42 cities across India, CERO has established a strong network to efficiently collect and recycle end-of-life vehicles (ELVs), contributing to environmental sustainability and responsible waste management practices.

RVSF

Greater Noida, Chennai, Ahmedabad, Indore, Hyderabad, Guwahati and Bengaluru.

The hallmarks of CERO’s commitment

Prompt Pickup

Prompt Pickup Instant Offer

Instant Offer Hassle-Free End-to-End Service

Hassle-Free End-to-End Service Adherence to All Legal Compliances

Adherence to All Legal Compliances

7

Registered Vehicle Scrapping Facilities

42

Collection Centres

Adapting CERO helped us save the below-mentioned amounts of natural resources

-

~28,100+ Tonnes

Iron Ore

-

~930+ Tonnes

Limestone

-

~10,900+ Tonnes

Coal

-

~50+ lakh Litres

of Furnace Oil

Energy

Energy

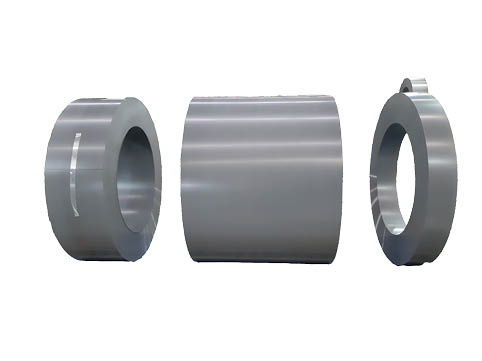

Mahindra Accelo’s high-end components in the energy sector, crafted from the world’s finest and most efficient electrical steel (CRGO), drive resource efficiency. Specialising in manufacturing components for the energy sector with CRGO, our Company’s facilities span 7 locations across India, the UAE, and Indonesia. Our extensive portfolio includes slittings, laminations, built cores, flux plates, and core coil assemblies for power & distribution transformers, exported to over 25 countries. Our commitment to processing high-grade electrical steel reduces transmission losses, conserving significant natural resources. Our Company’s expertise in various processes has positioned us as a leading supplier of stators and rotors to AC compressor and fan manufacturers. Thus, we extend our efficiency-boosting approach to the home appliance sector as well.

Power

Power

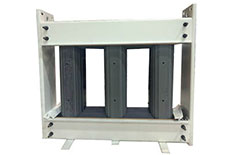

As the premier supplier of power components in India, Mahindra Accelo specialises in manufacturing top-quality components for transformers, renowned for their ability to significantly reduce transmission losses. Our Company delivers high-quality electrical steel cores to the power & distribution, renewable energy, and EV industries.

What We Offer

Slitting

Flux Plates

Laminations

Built-Up Cores

Core Coil Assembly

Cooling Duct

Our USPs

-

Pan-India Presence

Our extensive presence across India enables us to maintain proximity to our customers, ensuring efficient service and support.

-

Leadership position in CRGO

With a leadership position in high-grade Cold Rolled Grain Oriented (CRGO) steel components, we are a trusted and dominant player in this segment, known for our quality and reliability.

-

Global Expansion through Strategic Joint Ventures

Our strategic joint ventures for global expansion enable us to diversify our operations and de-risk our business, ensuring sustainable growth and resilience in the global market.

Electrical Stampings

Electrical Stampings

Mahindra Accelo is one of the leading suppliers of electrical stampings for home appliances in India. Our Company is equipped with advanced technology to manufacture highly efficient stators and rotors.

What We Offer

Slitting

Electrical Stamping

Stators & Rotors

Winding

Our USPs

-

Diverse Sources for Steel

We offer customers the flexibility to choose from diverse steel sources. This ensures that their specific requirements and preferences regarding quality, grade, and other specifications are met.

-

World-Class Quality Set Up

Along with our state-of-the-art plant, we have a world-class quality setup, which helps us deliver quality products to our customers.

-

Sufficient Capacity to Meet Growing Demand

With ample capacity, we are well-equipped to handle and fulfil the increasing demand for electrical stamping products. We provide our customers with timely and reliable supply solutions.

Kanhe II (Pune)

Provides a range of products and services including, Slitting, Stamping, manufacturing of Stators & Rotors, Die casting, Heat Treatment, and Motor cores

Chennai

Specialises in the slitting of Cold Rolled Non-Oriented (CRNO) coils

Purlins

Purlins

Our Company plays a pivotal role in the global transition to renewable energy. We provide premium steel structures, known as purlins, essential for mounting solar panels on rooftops or ground level. Additionally, engineered to optimise steel usage, our purlins offer an efficient and environmentally friendly solution for solar energy installations.

What We Offer

C Type Purlin (c+, c++)

Z Type Purlin (z+, z++)

Nashik

Offers C and Z type, purlins specifically tailored for the solar industry

Bringing Green

Solutions to Every

Doorstep with Ease

At CERO, our name and mission draw inspiration from the Spanish word ‘Cero,’ meaning ‘Zero.’ We are committed to achieving zero pollution, zero wastage, and reducing the import of metal scraps to zero.

CERO Impact

-

24,000+

Vehicles Scrapped

-

29,300+ Tonnes

CO2 Emissions Saved with ELV Recycling

-

17,500+ Tonnes

Ferrous Scrap Recycled

-

28,100+ Tonnes

Iron Ore Saved

CERO Impact

-

24,000+

Vehicles Scrapped

-

29,300+ Tonnes

CO2 Emissions Saved with ELV Recycling

-

17,500+ Tonnes

Ferrous Scrap Recycled

-

28,100+ Tonnes

Iron Ore Saved

A Joint Effort for a Sustainable Future

CERO is a collaboration between Mahindra Accelo and MSTC Limited, a Government of India enterprise. CERO has 42 registered vehicle scrapping facilities & collection centres across India, utilising top-notch technology for a hassle-free digital experience. This collaboration ensures legal compliance, offering customers a seamless and environmentally sustainable scrapping process.

Why Recycle your Vehicles?

Reduce Pollution

Recycling end-of-life vehicles (ELVs) contributes to the reduction of air and water pollution.

Conservation of Resources

Recycling saves energy and conserves the fossil fuels required for steel production. It requires 74% less energy to recycle steel compared to making new steel.

Save Natural Resources

Recycling vehicles helps save natural resources by replacing the need for mining iron ore, coal, and other materials.

Seamless Deregistration

Receiving legally valid certificates of destruction and required documents to facilitate the deregistration of vehicles from the relevant R.T.O.

Certificate of Deposit & Vehicle Scrapping

As an authorised recycler, CERO can issue a Certificate of Deposit (CoD) to the customers upon receiving the vehicle for recycling. Based on this CoD, customers can claim the incentives as per state policy. Post-recycling of vehicles, CERO issues a Certificate of Vehicle Scrapping to the Government and the customer, ensuring that the data is properly captured by the Government.

Growth in FY 2023-24 over FY 2022-23)

Growth in FY 2023-24 over FY 2022-23)